Production Capacities:

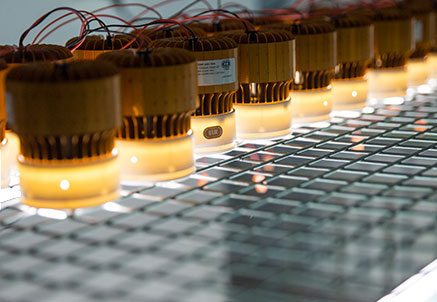

Our assembly space is unlimited with shared manufacturing interest in Metal working, Machining, Extrusion, Die casting, Plastics, Glass, Optics and Assembly. Staffed with a skilled assembly team managed by a leader with more than ten years experience in lighting manufacturing. SPC controlled Assembly.

Deliverables include specialized inspection equipment on site to generate SPC as required data during production run.

Our die casting includes parts in 360, 380, Zinc and Brass with polishing, trimming, sanding and other die cast cleanup service on side. Machines range from 160T to 1000T.

Along with qualified vendors in Alum and plastic extrusion, plastic injection, sand casting, various surface treatment including powder coating, wet paint, chrome plating, Anodizing, we are able to provide excellent quality of lighting product in short lead time.Small Production runs are also available.

Decorative glass is available to closely match customer criteria.

Glass and plastic optics assemblies and special Dichroic coatings are available to deliver technical light distribution and emitted light coloration.